Engineering Industry

In machine engineering, compressed air tools are frequently favored over electric tools due to their ease of use, independence from electrical power sources, and lightweight nature. Some applications rely on compressed air as their energy source, and they don’t demand exceptionally high air quality. In such cases, the installation of a refrigeration dryer and a filter is typically adequate. Nonetheless, it’s crucial to ensure the proper design for processing and treatment, as inadequate planning can lead to avoidable energy expenses.

Compressed Air Applications in Engineering Industry

Drive Energy

The Air Energy Audit offers a cost-effective and efficient solution for managing compressed air systems. Through an Air Audit, we can swiftly pinpoint inefficiencies within your compressed air system and provide guidance on optimizing its overall performance. This includes reducing leaks and implementing effective air management practices. Our goal is to help clients minimize power consumption and decrease the load and wear on their compressed air systems, ultimately extending the system’s lifespan.

Respiratory air

Numerous production environments involve operations where tasks are performed amidst dust, paints, and other significantly hazardous substances. In these scenarios, it is imperative to ensure the safety and well-being of employees by protecting them from aerosols, fine dust, and associated health risks. Workers may receive a supply of breathable air through respiratory protective devices, or in some cases, they may need to wear fully sealed protective suits akin to astronauts. To conserve space, compressed air is frequently stored in containers, utilizing specialized respiratory air compressors. The compressed air must meet stringent purity standards to be suitable for use as a respiratory gas.

Cooling & Heating Air

Cooling and heating through the use of compressed air involve the utilization of a device known as a vortex tube. In this device, gases are segregated by rotating into distinct hot and cold air streams. These gases are then discharged through variously sized openings based on their respective temperature states.

Sealing gas / Inert gas

Compressed air offers a non-contact method for sealing machinery, systems, and fixtures, ensuring a frictionless and wear-free seal. In mechanical engineering, where delicate components and surfaces need safeguarding against dust, dirt, humidity, or moisture, this technique is employed by generating an “air curtain” over these areas. Additionally, compressed air serves as a valuable tool for inspecting seals and identifying any potential leaks.

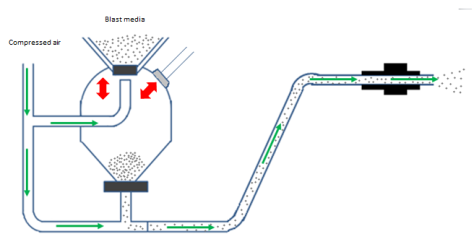

Compressed air Blasting & Painting

Compressed air finds applications in surface treatments, specifically in processes involving the application of abrasives and the atomization of paints: Compressed air blasting or grit blasting refers to the treatment of surfaces on materials or workpieces. It involves using sand as an abrasive medium to remove rust, dirt, paint, scale, and other impurities, or to create surface textures. When using compressed air for painting, it is crucial to ensure that the air meets stringent purity standards. This involves adhering to specified limits for particles, oil aerosols, oil vapor, materials containing silicone, and condensate to maintain quality.

Our customers in the Engineering Industry

Air Energy Audit is reducing Energy Bills for big names in Pakistan's Engineering Sector