Air Energy Audit & Packaging Industry

The packaging sector in Pakistan has experienced remarkable expansion in recent times. AirAudit offers machine and end-user consumption analysis along with solutions tailored for the packaging industry. Our solutions are designed to lower energy usage, enhance equipment reliability and operational uptime, mitigate environmental impact, and generate cost efficiencies. Here are several examples of how compressed air is applied within the packaging industry.

Applications of Compressed Air in Packaging Industry

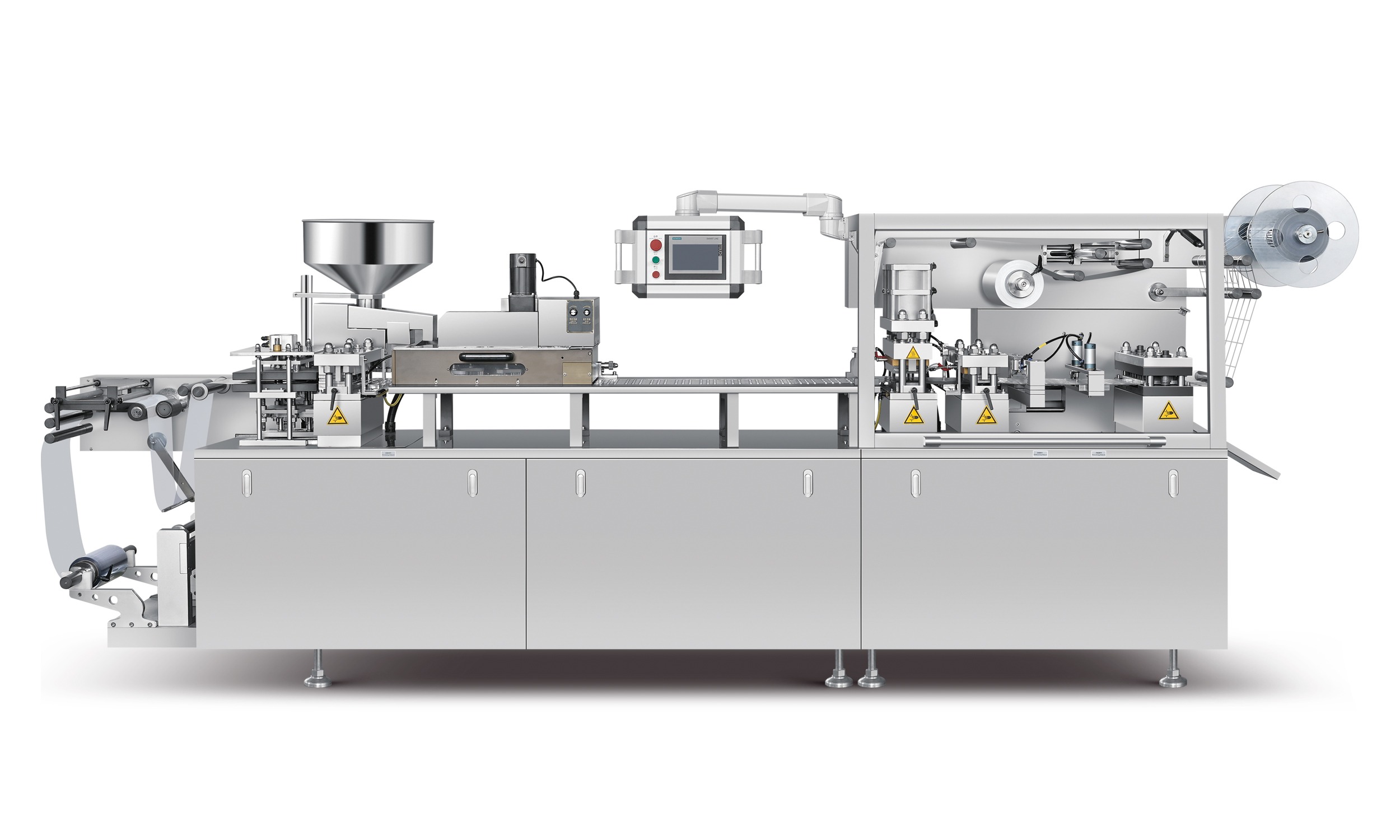

Blister Machine

Blister packaging frequently utilizes vacuum-based systems for the generation of a vacuum seal. The filling and sealing units operate using this vacuum technology.

Chamber Machine

Creating a vacuum and sealing the bag. Introducing inert gas before sealing the bag.

Rolling Machine

In the sealing tool, the air is removed, and if needed, a modified atmosphere can be introduced before sealing the container.

Forming

In vacuum forming, an extra pump is required for that specific section of the machine.

Non Food Packaging

Before sealing the packaging, a vacuum pump is employed to remove air from the packaging. This proper packaging method not only enhances the protection during transportation but also guarantees that items like electronic components and pharmaceuticals are shipped to customers in a sterile condition, free from dust and contaminants.

Tray sealing

Creating a vacuum and then sealing the bag, or Introducing inert gas into the bag and subsequently sealing it.

Trim Removal

Film strips, once severed, are drawn into a container using our CEVF radial fan series. These collected film strips are ready for recycling, promoting sustainability and resource reuse.

Air Cushion Machine

Film tubes are inflated with compressed air and welded together to form cushions. These cushions can be used as protective filling material.

Our Customers in Packaging Industry

Air Energy Audit is reducing Electricity Bills for big names in Pakistan's Packaging Industry